Stadiums are vibrant hubs of activity, hosting thousands of visitors for sports, concerts, and other large-scale events. With these events comes the challenge of managing...

Bergmann PS8100

Rotary Bag Compactor

The Bergmann PS8100 is the original bag compactor. It has now been superceded by the Bergmann 1400-E Rotary Baler

The Bergmann 1400-E has a larger capacity and a new design while including all the features of the original PS8100. Click the link in the bold text above to get all the information on the 1400-E.

Accessories and features

How The Bergmann

PS8100 Works

A new bag is placed in the machine with a pallet on the floor and the doors closed; waste is loaded through the chute door; the rotary drum breaks up and compacts the waste into the bag; the bag is protected by a metal bag shield.

The full bag, typically between 350kg and 500kg in weight; is pulled out with a pallet truck and the bag sealed. The bag can be fork-lifted into a 35 yard container (typical in factories) or collected where waste vehicles have bag and forklift attachments (commonly available in London for example).

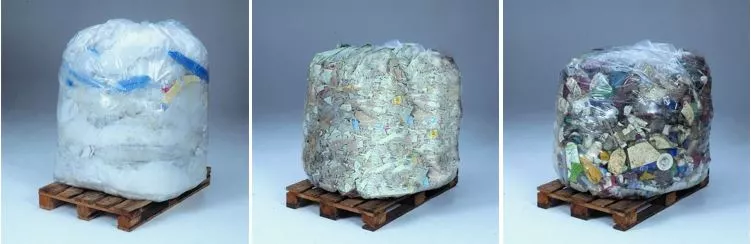

Full bags from Bergmann PS8100: Left: Plastic - 140kg bag; Middle; Cardboard - 250kg; Right: General - 300-500kg

Specification

Typical Customers

Related

Products

Request a free quote

If you’d like to get a quote from us today on any of our machines, please click the link below and a member of our team will be in touch.

Latest from our blog

Big changes are coming in March 2025 as the UK government tightens food waste regulations. This new legislation will prohibit businesses from disposing of food waste via drains...

When it comes to managing bulky waste efficiently, roll packers are an excellent solution. By compacting waste directly in open containers, they help reduce volume, lower waste...